Sticky Solar Power offers solar stringer machines. Our solution is free from lead and requires 60% less silver producing a PV module.

By avoiding high temperature soldering we lower the risk of cracking the cells. The interconnection is instead performed at room temperature. Eliminating bowing/warping of the solar cells.

Our trademarked The Tape Solution™ can integrate into any production line. Developed for Hetero Junction(HJT), Perovskite, Topcon and IBC solar module production.

Contact us on +46 (0)70 43 33 217 or hello@stickysolarpower.com for technical specifications.

The standard way of interconnecting solar cells is soldering. A solar stringer places wires containing lead upon the solar cells. The soldering reaches a temperature of over 240 degrees celsius in a matter of seconds. Increasing the risk of cracking the cells.

Hetero Junction (HJT) and Perovskite cannot endure high and rapid changes in temperature. Furthermore bowing/warping will occur during soldering of back contact (IBC) modules.

The Tape Solutions resolves all these issues. The soldering occurs in the lamination process. Reaching a max temperature of 160 over a 10 minute span. This prevents cracking of solar cells and bowing/warping.

The Tape solution combines the soldering and lamination into one. Thus eliminating the use of lead and silver.

By removing the soldering The Tape Solution™ cut the cost of silver by 60% when making a solar module. Of all solar module breakage an estimated 41% is a result of soldering during interconnection. Interconnection done at room temperature reduces the possibility of solar cells cracking.

As the soldering occurs during lamination the Tape solution streamlines production. By average this reduces the cost by 5-7% in making a standard PV module.

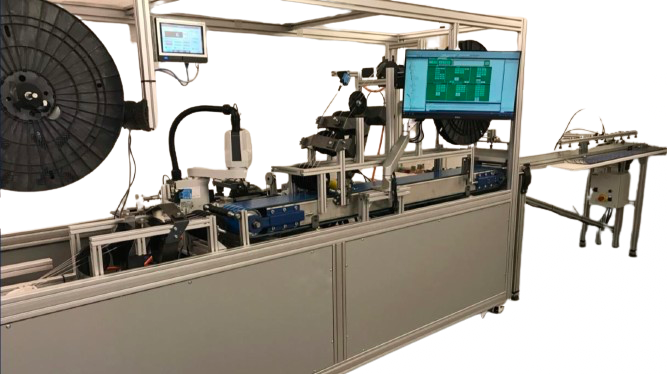

Our solar stringer machine operates 24/7, 365 days a year. Capable of single track interconnecting 2000-2500 solar cells per hour. The Tape Solution can integrate into any production line. Leaving a small factory footprint of only 5m².

Solar modules created by the Tape solution have passed the IEC 61215 thermal cycling test. The solar panels must not lose more than 5% of their original max power after being exposed to 200 cycles.

After 600 cycles the panels lose only 1.1% of their original power. The solar panels made with the tape solution are both cost and energy efficient.

The Tape Solution™ is an environment friendly technology that reduces the use of lead by 90%. Lead is a cumulative toxic substance. It contaminates air, water and soil, while causing lead poisoning. Lead accumulates in the brain, liver, kidney and bones. Estimated to account for 1.06 million deaths and 24.4 million years of health life lost due to long-term effects on health.

Our solutions are built on advanced technology and packed with cutting-edge features to deliver optimal performance and reliability.

Everything we do amounts to you saving time and production costs.

For that to happen, the industry needs to shift gears. The Tape Solution™ revolutionizes solar photovoltaic module manufacturing by enabling substantially higher throughput at lower cost, more ambitious levels of sustainability and minimized factory footprint.

Sticky Solar Power is a Swedish developer and supplier of innovative solar photovoltaic technology solutions. The company is based in Stockholm, and is owned by its founders.

The Tape Solution™ revolutionizes solar photovoltaic module manufacturing by enabling substantially higher throughput at lower cost, more ambitious levels of sustainability and minimized factory footprint.